The key components of the stone cladding system for building curtain walls, let me introduce them to you in detail:

Core component functions

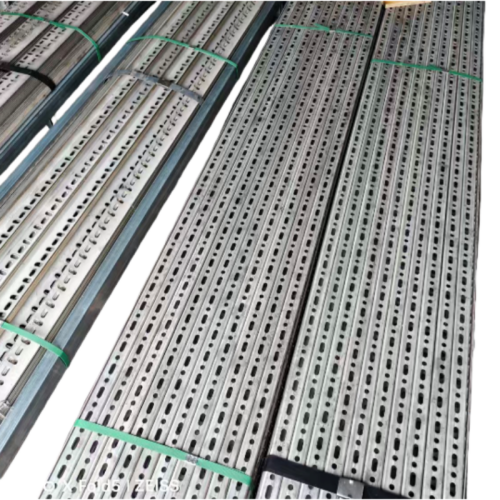

Stainless steel U-shaped channel

Function: As the main keel, it is fixed to the main structure of the building and bears the vertical load of the entire curtain wall system.

Material: Usually made of 304 or 316 stainless steel, with strong corrosion resistance.

Features: The U-shaped cross-section design facilitates installation and adjustment, and can accommodate the unevenness of building structures.

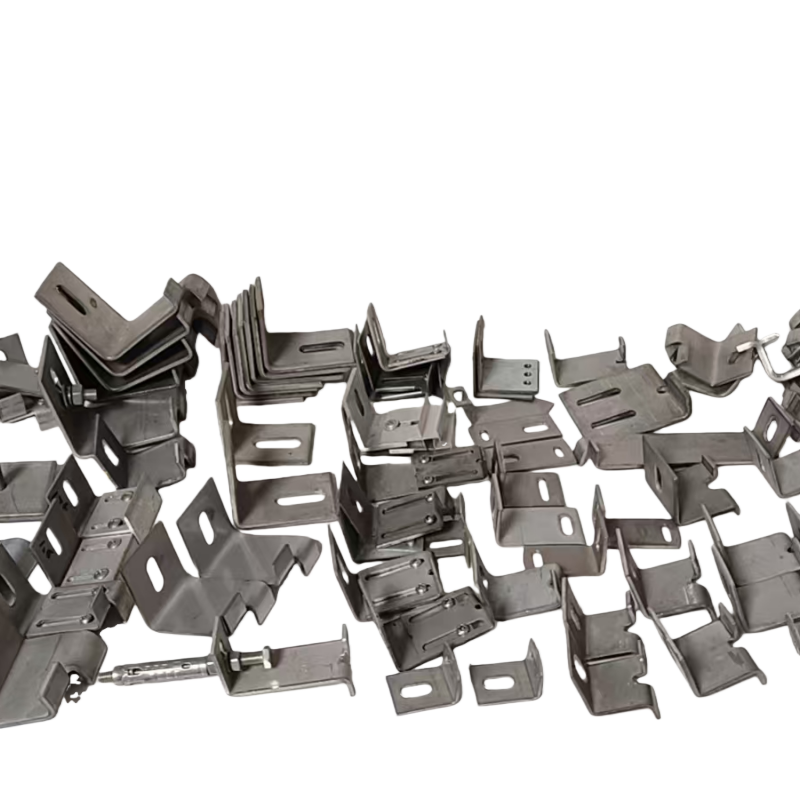

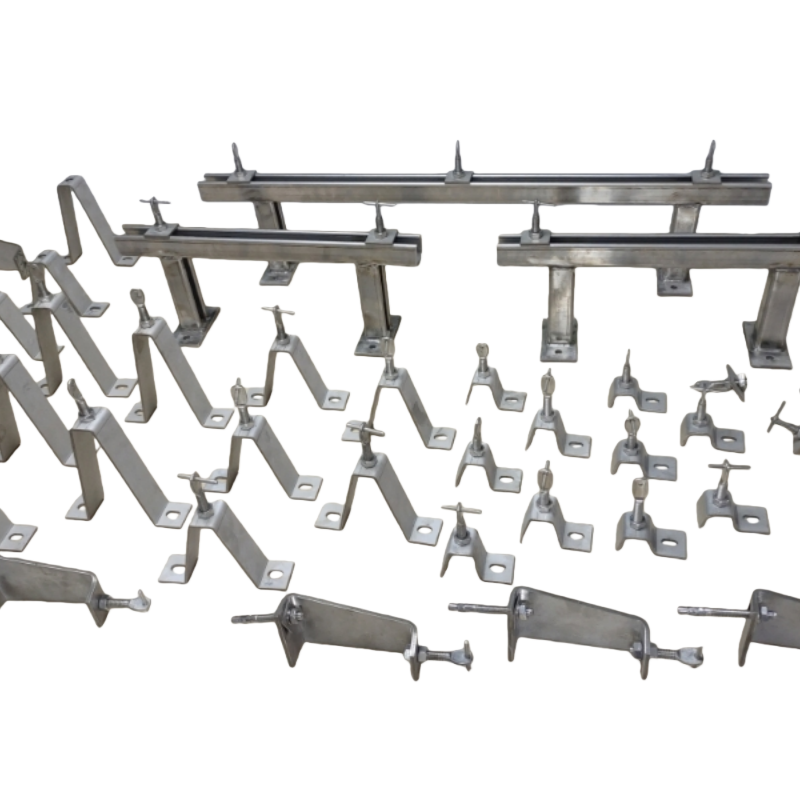

2. L-shaped connecting bracket

Function: Connect the U-shaped channel and the Z-shaped stone clip to secure the stone panel.

Material: Stainless steel or hot-dip galvanized steel

Features: The L-shaped design facilitates three-dimensional adjustment, ensuring the flatness and verticality of the stone panel.

3. Z-shaped stone clamp

Function: Directly fix the stone panel and transfer the load of the stone to the connecting bracket.

Material: Stainless steel, with a thickness typically ranging from 2 to 3 mm.

Feature: The Z-shaped structure offers sufficient strength and adjustment margin, preventing stress concentration in the stone.

System Advantages

This dry-hanging system features easy installation, flexible adjustment, good seismic performance and convenient maintenance. It is widely used in curtain wall projects of high-rise buildings and commercial complexes. The cavity formed between the stone panels and the main structure is conducive to thermal insulation, heat preservation and waterproofing.

Post time: Jan-07-2026