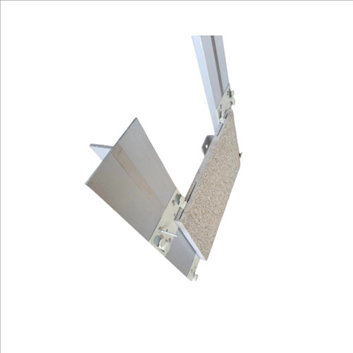

T-shaped aluminum alloy bracket system for tile wall cladding support

The T-shaped aluminum alloy bracket system is a modern prefabricated curtain wall support system specifically designed for tile wall cladding. This system securely installs tile panels on the building structure surface through aluminum alloy brackets, forming an aesthetically pleasing and durable exterior wall decoration system.

System Features

Lightweight and high strength: Aluminum alloy materials have a low density and light weight, which can significantly reduce the overall load of buildings. At the same time, they possess high strength and good toughness, capable of withstanding the weight of ceramic tile panels as well as external forces such as wind loads and seismic actions.

Excellent corrosion resistance: The surface of aluminum alloy naturally forms a dense oxide film, which can effectively resist the erosion of oxygen, moisture, and acidic or alkaline substances in the air. Even in harsh environmental conditions, it can maintain stable performance for a long time.

Easy to process and install: Aluminum alloy has excellent processing performance and can be easily processed into various shapes and specifications of bracket components according to design requirements. The connection method is relatively simple, and the construction efficiency is high.

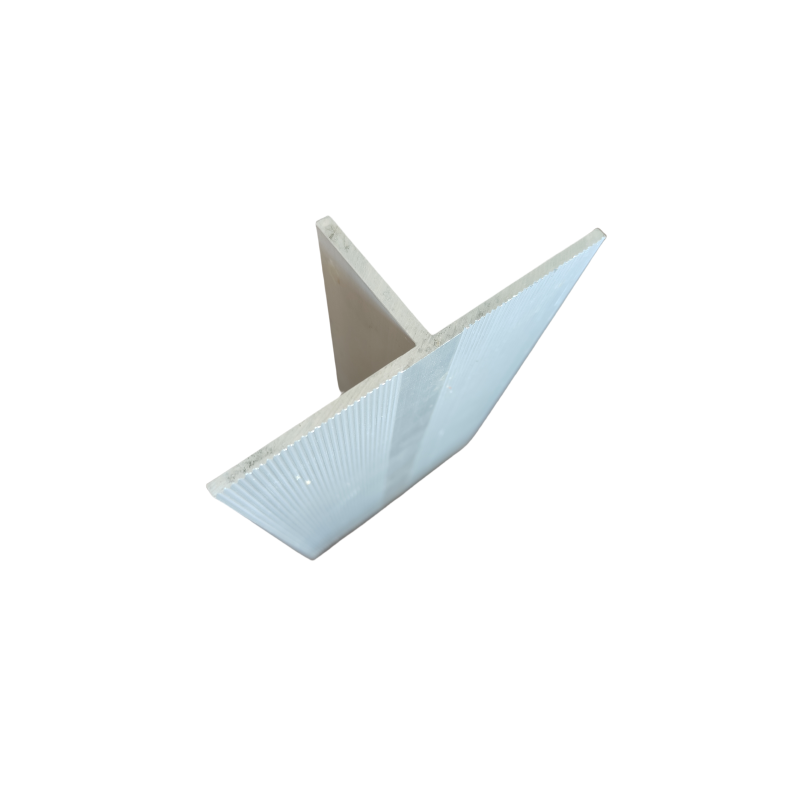

Technical Parameters

The T-shaped aluminum alloy bracket is made of 6063-T5 or 6061-T6 material, with the surface treated by anodizing to form an oxide film of 12-15 μm in thickness. The salt spray test duration exceeds 1000 hours. The height of the bracket ranges from 65mm to 269mm, and the width is typically 65mm × 65mm, equipped with an insulating pad layer.

Installation process

The brackets are directly fixed to the purlins with screws. The installation spacing is determined by the width of the aluminum-magnesium-manganese plate, generally 430mm. The front and rear distances are usually 1000mm – 1500mm. On average, 1.2 sets of brackets are used per square meter. During installation, it is necessary to ensure that the brackets are perpendicular to the purlins and parallel to each other. They are fixed with self-tapping screws and no additional fixation measures are required.

Application Advantages

Compared with the traditional cement mortar bonding method, the T-shaped aluminum alloy bracket system effectively avoids problems such as tile hollowing and falling off, significantly enhancing the safety and durability of the curtain wall. The system supports the free expansion and contraction of the tile panels, solving the stress problems caused by thermal expansion and contraction, and is particularly suitable for the exterior decoration of large-span buildings and high-rise buildings.

Post time: Jan-08-2026