System Overview

The dry-hung aluminum alloy support system for stone curtain walls fixes stone panels to the building structure through aluminum alloy supports, forming an exterior wall system that combines both decorative and functional features. It does not require traditional cement mortar bonding, avoiding problems such as stone detachment caused by weak bonding of cement mortar, and improving the safety and durability of the curtain wall.

Advantages of aluminum alloy brackets

- ** Light weight ** : Aluminum alloy has a low density. Compared with traditional support materials such as steel, it significantly reduces the self-weight of buildings and lowers the load on the foundation structure, making it particularly suitable for high-rise buildings.

- ** High strength ** : Through a special alloy formula and processing technology, the aluminum alloy bracket has sufficient strength and rigidity, capable of withstanding the weight of the stone panel as well as external forces such as wind loads and seismic forces.

- ** Good corrosion resistance ** : The surface of aluminum alloy can form a dense oxide film, effectively resisting the erosion of environmental factors such as the atmosphere, rain, and ultraviolet rays, extending the service life of the support system and reducing maintenance costs.

- ** Good processing performance ** : Aluminum alloy is easy to be processed into components of various shapes and specifications, which can meet the needs of different architectural designs and achieve diverse shapes and layouts.

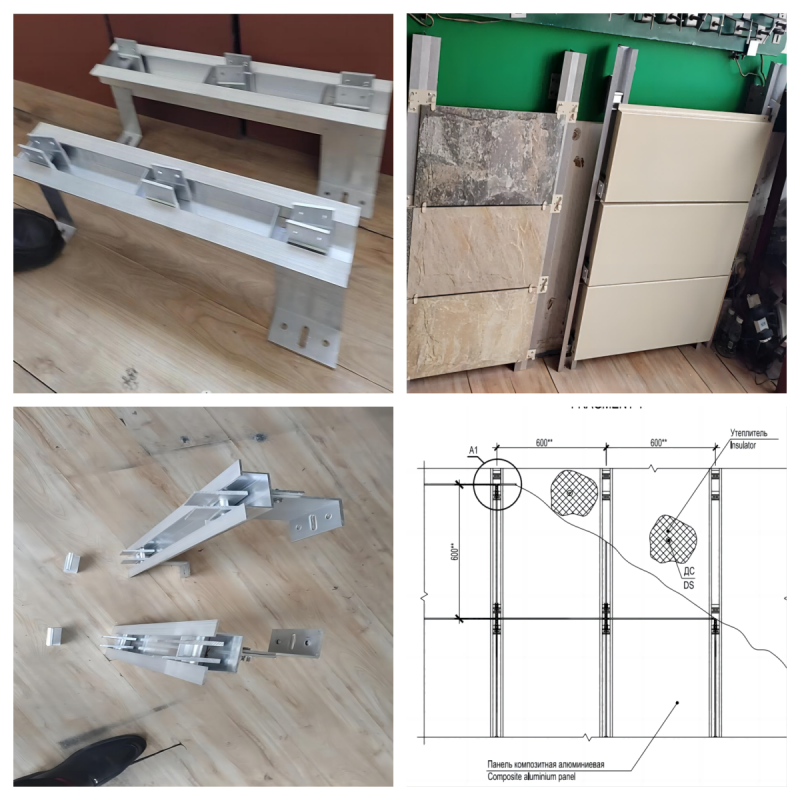

System composition

- ** Main keel ** : Usually made of larger-sized aluminum alloy profiles, it is vertically installed on the main structure of the building, serving as the primary load-bearing component of the entire support system. It bears the vertical and horizontal loads of the stone curtain wall and transfers them to the main structure.

- ** Secondary keel ** : Horizontally installed on the main keel, it is connected with the main keel to form a frame structure and is used to fix the stone panel. The spacing of the secondary keel is reasonably designed based on the size and weight of the stone panel to ensure the stability of the panel.

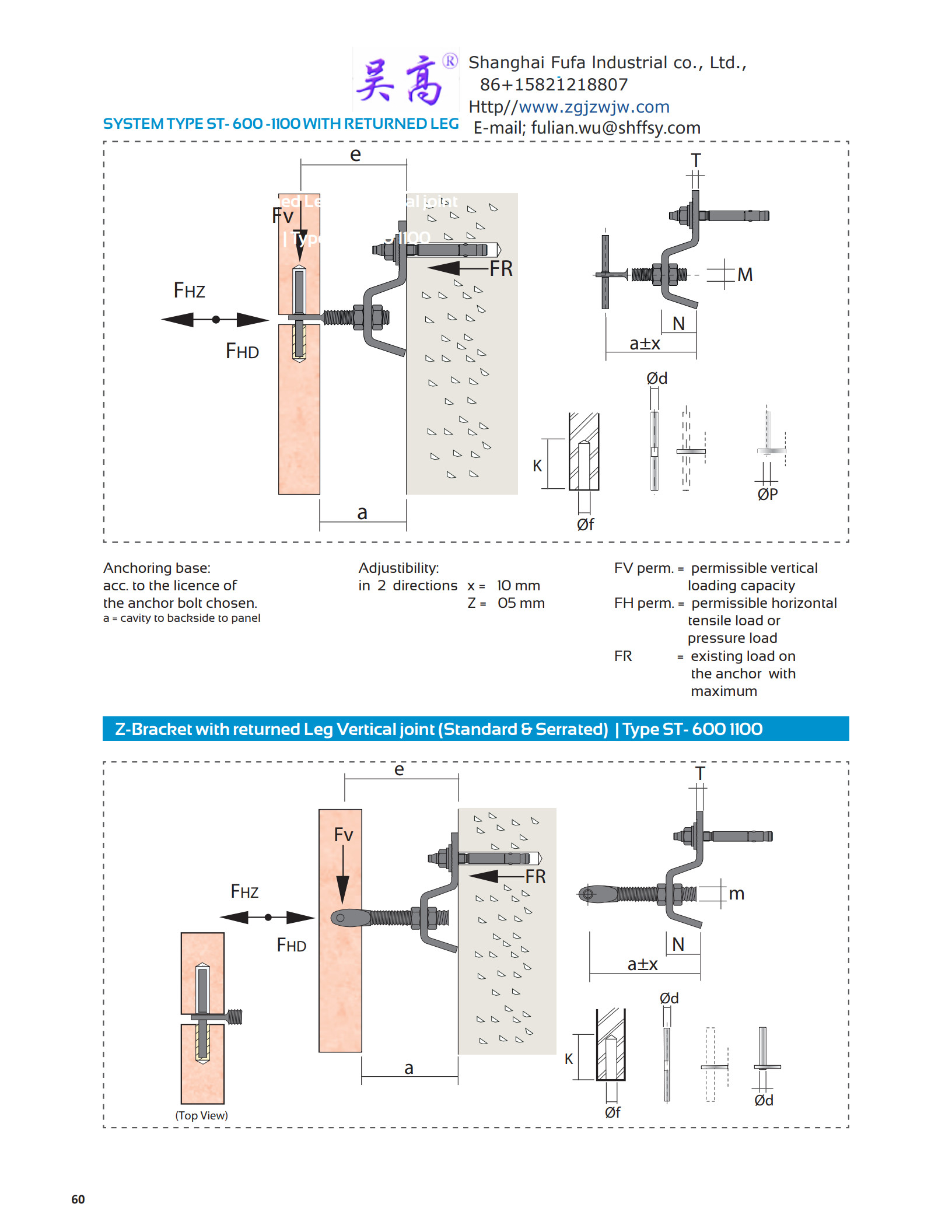

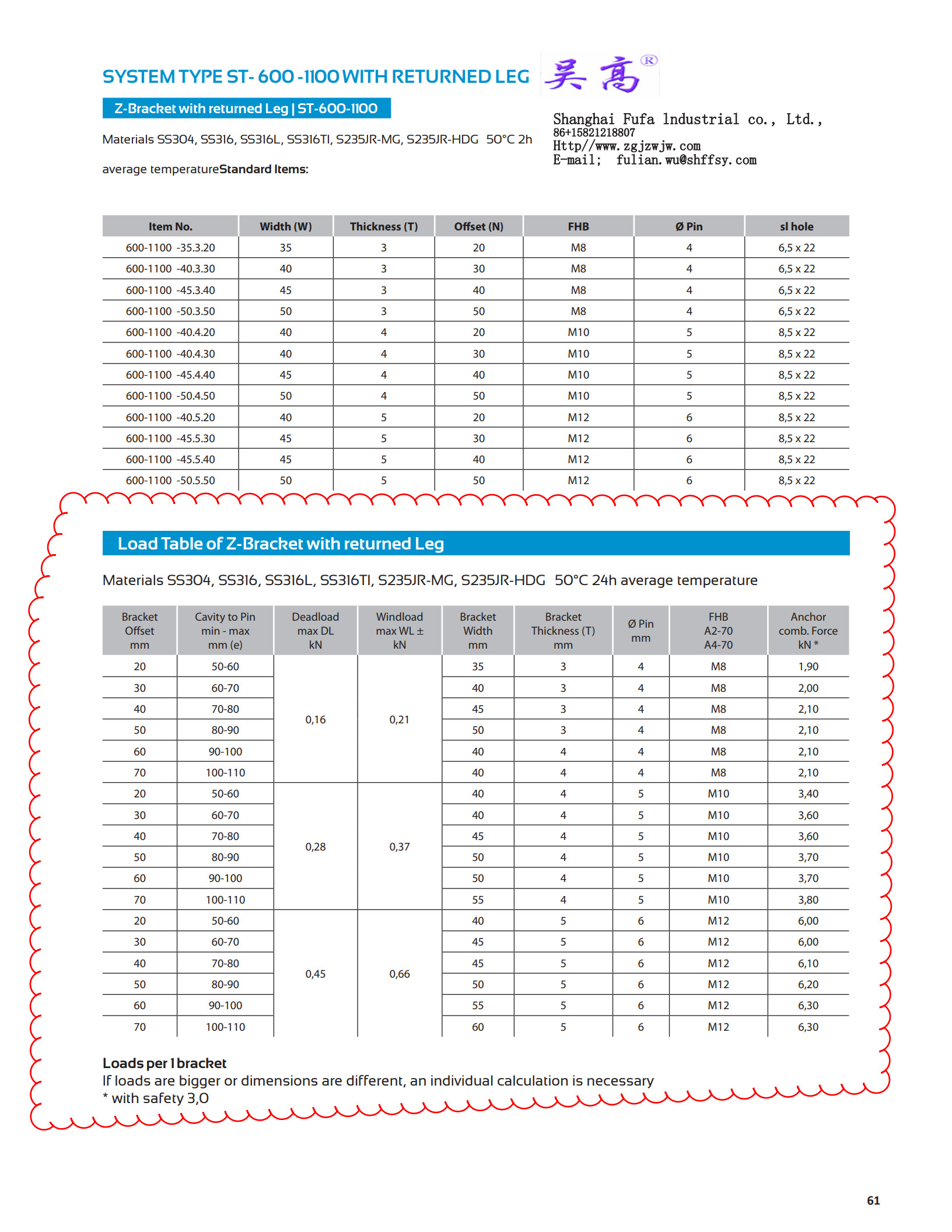

- ** Connectors ** : Including corner codes, bolts, etc., used to connect the main keel with the main structure, the main keel with the secondary keel, and the secondary keel with the stone panel. The design and installation of the connecting parts should ensure the firmness and reliability of the connection, and at the same time have a certain adjustment function to adapt to construction errors and structural deformations.

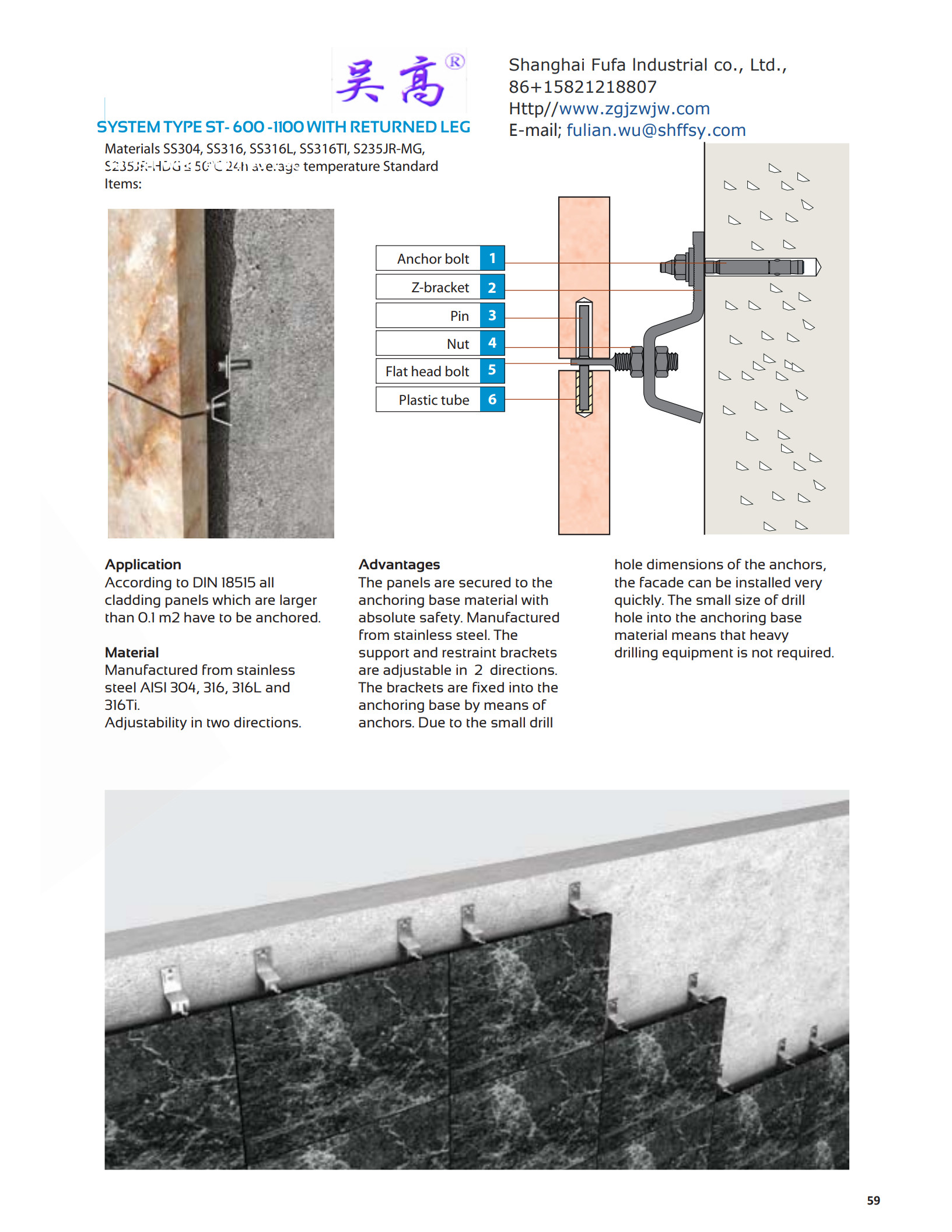

- ** Hangers ** : Directly connect to the stone panel and fix the panel on the secondary keel. There are various forms of hangers, such as back-bolt type, support plate type, and slot type, etc. The appropriate hanger should be selected based on the type, thickness of the stone and installation requirements.

Installation process

1. ** Measurement and Layout ** : Based on the design drawings and the actual situation on site, measure and layout the installation position lines of the main keel on the main structure of the building to ensure the accuracy of the keel installation.

2. ** Main Keel Installation ** : Fix the main keel to the main structure through connecting pieces, and adjust the verticality and levelness of the keel to meet the design requirements.

3. ** Secondary Keel installation ** : Install the secondary keel on the main keel, firmly connect the secondary keel to the main keel through connecting pieces, and adjust the spacing and levelness of the secondary keel.

4. ** Stone Panel Installation ** : Connect and fix the stone panels to the secondary keel through hangers, adjust the flatness and verticality of the panels, and ensure that the joints between the panels are uniform and consistent.

5. ** Sealing treatment ** : Fill the joints of the stone panels with sealant to prevent rainwater, air, etc. from seeping into the interior of the curtain wall, thereby enhancing the waterproof and airtight performance of the curtain wall.

Application scenarios

It is widely applied to the exterior decoration of various public buildings such as commercial buildings, office buildings, hotels, cultural venues and high-end residences, and can enhance the appearance quality and artistic value of buildings.

If you still have any questions about the cost, maintenance or other aspects of the dry-hung aluminum alloy support system for stone curtain walls, please feel free to ask me more.

Post time: May-05-2025