Main Features

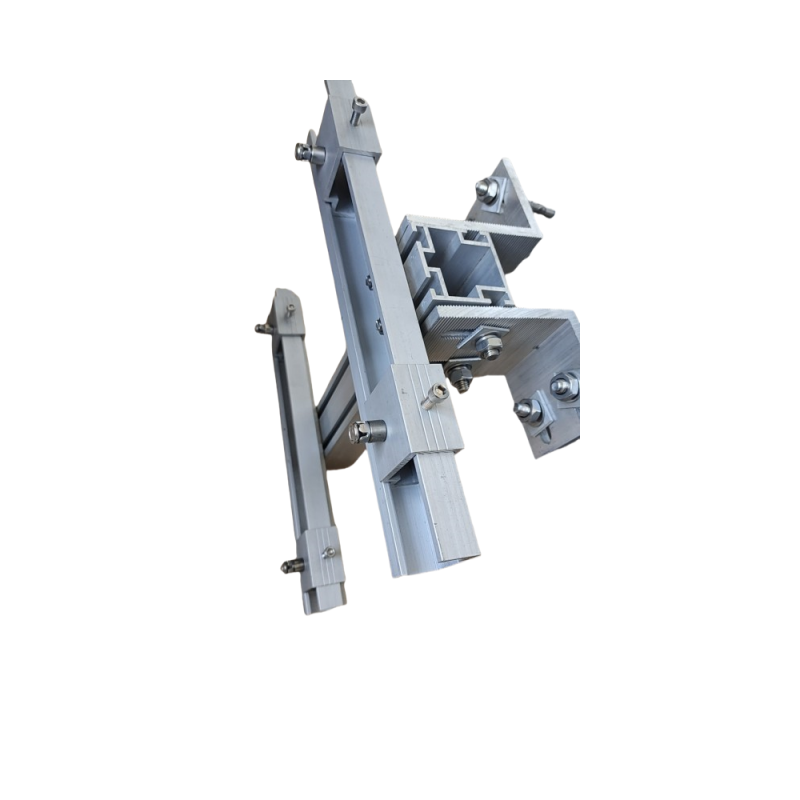

1) Simple structure, easy in installation and maintenance.

2) No need welding, safety and environmental.

3) Structure reasonable, long life more than 50 years.

4) To remove the old project to new project still can be used and no need cutting, just unscrew the bolts.

5) Comprehensive costs much more cheaper than used one.

Product Advantages

When it comes to wall cladding, finding the right materials and accessories is crucial to achieving the perfect finish. One of the key components to consider is the L-shaped aluminum corner for marble granite wall cladding. This versatile accessory not only enhances the beauty of your walls, but also adds durability and protection. In this blog post, we will explore the benefits of using L-shaped aluminum corners in marble granite wall cladding projects.

Aluminum corners are a popular choice in the construction industry due to their lightweight yet strong properties. The L-shaped design is especially useful for marble granite wall cladding as it allows for seamless corner installation. By using L-shaped aluminum corners, you get clean, sharp edges that enhance the overall look of your walls.

One of the main advantages of aluminum corners is the ability to protect the fragile corners from damage. Whether from accidental bumps or general wear and tear, corners are often vulnerable to damage over time. By installing L-shaped aluminum corners, you can prevent chipping, cracking, and other forms of damage, making your walls more durable and aesthetically pleasing.

In addition, using aluminum corners in wall covering projects has a range of other benefits. Aluminum is highly corrosion resistant, meaning it can withstand moisture and harsh weather conditions. This is especially important in wet areas such as bathrooms and outside walls. Plus, aluminum is easy to clean and maintain, making it a low-maintenance choice for busy homeowners or commercial properties.

It is important to consider quality and workmanship when selecting L-shaped aluminum corners for marble granite wall covering projects. Choosing a reputable supplier ensures that you receive a product that is not only visually appealing but also durable and long-lasting.

|

Wugao

|

Others

|

|||

|

Frame Material

|

Aluminum Alloy

|

Zinc Plated Steel

|

||

|

Frame Assemble

|

Factory Pre-Assembly

|

Onsite Assembly

|

||

|

Installation

|

More faster,easier and flexiable to connect and fix tightly with Wall and ladding via pattened Pre-assembled Frame to use

accessories,Save cost of operation time and labor |

Onsite assembly with complicated operation

|

||

|

Welding Onsite

|

No Need

|

Yes

|

||

|

Anti-rusty Treatment After Welding

|

No Need

|

Yes

|

||

|

Noise and Pollution Onsite

|

No

|

Yes

|

||

|

Cladding Maintenence

|

More easier

|

Normal

|

||

|

System Overall Life

|

More 50 years withtout frame maintenence

|

About 20 year with cost of parts maintenence

|

||

|

Applied Cladding

|

Stone, granite, marble, tile, terracotta, ceramics, glass, aluminum honeycomb boards etc.

|

Specific

|

||

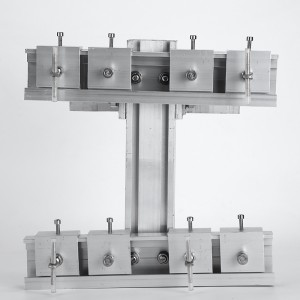

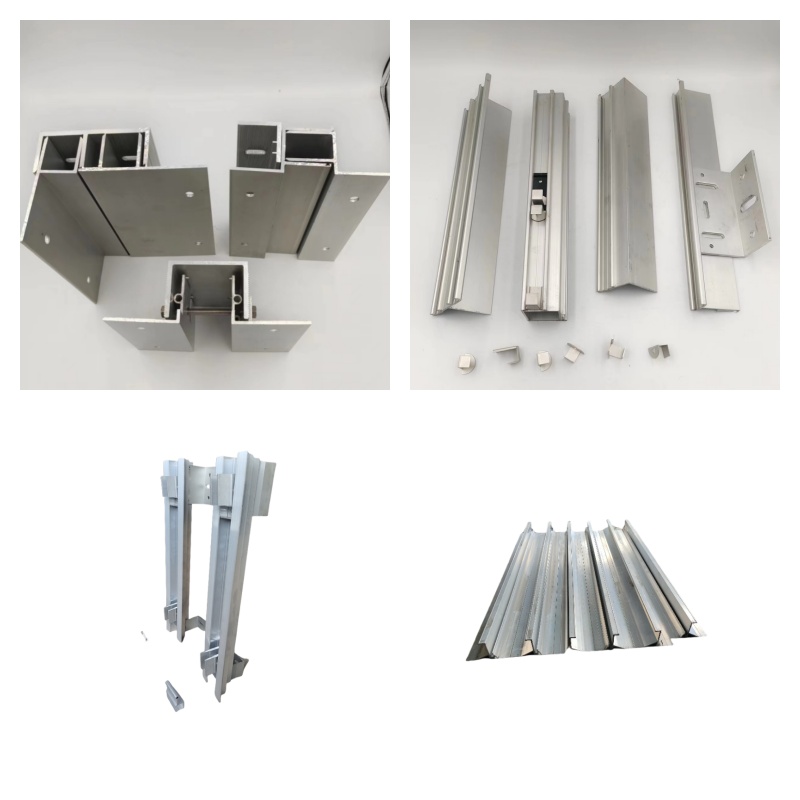

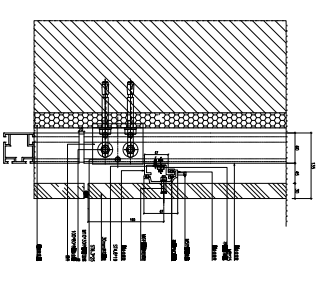

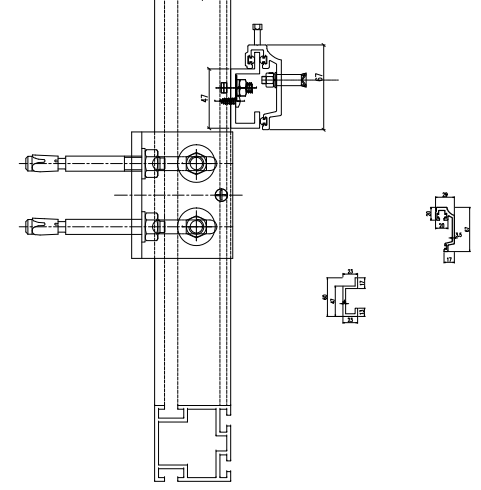

Detailed Images

Aluminum alloy frames,

Groove type and back bolt type dry hanging for tiles and marble.

Aluminum alloy frame,

Groove type dry hanging for granite.

Aluminum alloy frame,

Our Service

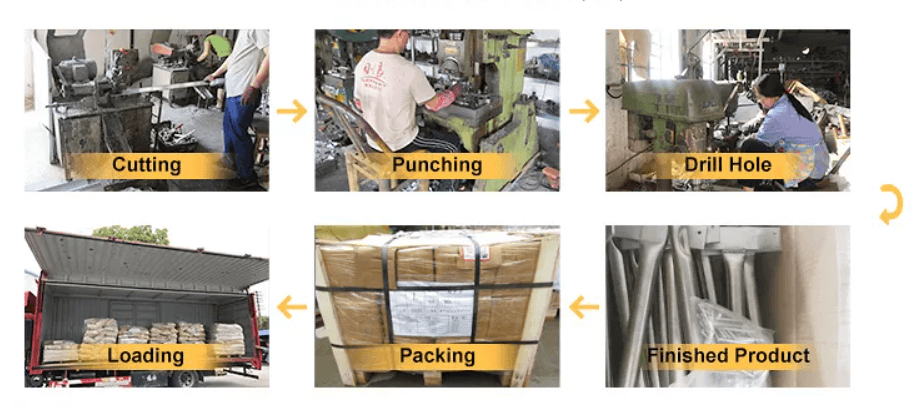

PRODUCTION PROCESS

We can make many styles of building embedded parts,

you provide drawings and requirements, and we can do

the rest

We can use the most advanced mold design software Auto CAD to

design accessories for you

Packing & Delivery

|

Packaging

|

|

|

Size

|

123(L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

-

Durable Pin Type Aluminum Cladding Bracket for ...

-

Manufacturers export wholesale aluminum alloy L...

-

The factory produces aluminum alloy processing ...

-

Aluminum alloy and stainless steel support syst...

-

Factory Direct Sale Tile Wall Cladding System S...

-

Aluminum Joint Back-bolt Bracket for Marble/Cur...