Product Description

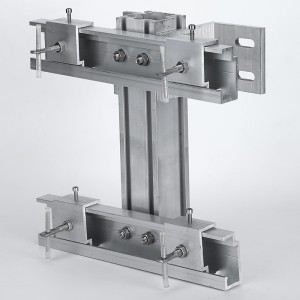

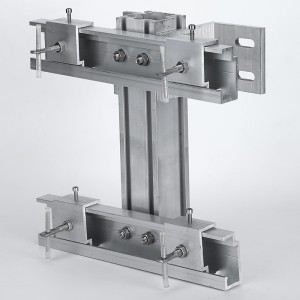

The stainless steel mounting bracket is designed for tile wall use and integrates seamlessly into any type of tile installation. Whether in the bathroom, kitchen, or any other area in your home or office that requires tile, these brackets will provide a reliable and sturdy base for your tile.

One of the main advantages of stainless steel mounting brackets is their durability. Made of high-quality stainless steel, these brackets resist corrosion, rust, and other damage caused by moisture or humidity. This ensures your tile installation will remain intact and attractive for years to come without the need for frequent maintenance or repairs.

Stainless steel mounting brackets not only provide a functional solution but also help to enhance the overall aesthetics of your tiled walls. These brackets feature a sleek, modern design that blends seamlessly into any type of tile, making your installation look clean, professional, and visually appealing.

In terms of installation, stainless steel mounting brackets are relatively easy to use. With the right DIY instructions or the help of a professional, you can easily mount these brackets to the wall and secure your tile in no time. This makes them ideal for experienced DIYers and individuals looking for professional help.

Our Advantages

|

Wugao

|

Others

|

|||

|

Frame Material

|

Stainless Steel

|

Zinc Plated Steel

|

||

|

Frame Assemble

|

Factory Pre-Assembly

|

Onsite Assembly

|

||

|

Installation

|

More faster,easier and flexiable to connect and fix tightly with Wall and ladding via pattened Pre-assembled Frame to use

accessories,Save cost of operation time and labor |

Onsite assembly with complicated operation

|

||

|

Welding Onsite

|

No Need

|

Yes

|

||

|

Anti-rusty Treatment After Welding

|

No Need

|

Yes

|

||

|

Noise and Pollution Onsite

|

No

|

Yes

|

||

|

Cladding Maintenence

|

More easier

|

Normal

|

||

|

System Overall Life

|

More 50 years withtout frame maintenence

|

About 20 year with cost of parts maintenence

|

||

|

Applied Cladding

|

Stone, granite, marble, tile, terracotta, ceramics, glass, aluminum honeycomb boards etc.

|

Specific

|

||

Our Service

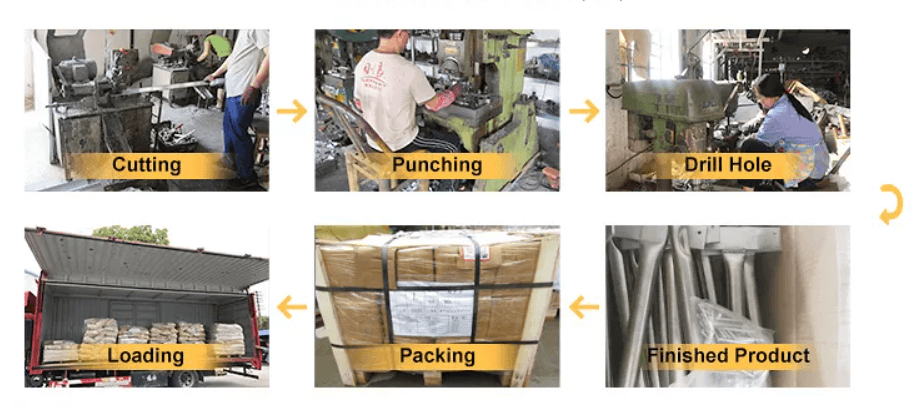

PRODUCTION PROCESS

We can make many styles of building embedded parts,

you provide drawings and requirements, and we can do

the rest

We can use the most advanced mold design software Auto CAD to

design accessories for you

Packing & Delivery

|

Packaging

|

|

|

Size

|

123(L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

-

Ceramic Tile Wall Installation System for Stone...

-

Factory Direct Sale Tile Wall Cladding System S...

-

316 Stainless Steel bolt Stone anchorage system...

-

Aluminum Alloy Cladding System for Curtain Walls

-

Top Quality Fashionable Aluminum Alloy Fixing S...

-

Cost-effective Stainless Steel Metal Tube Ancho...